DIGITAL MANUFACTURING

Digital Manufacturing Application Benefits

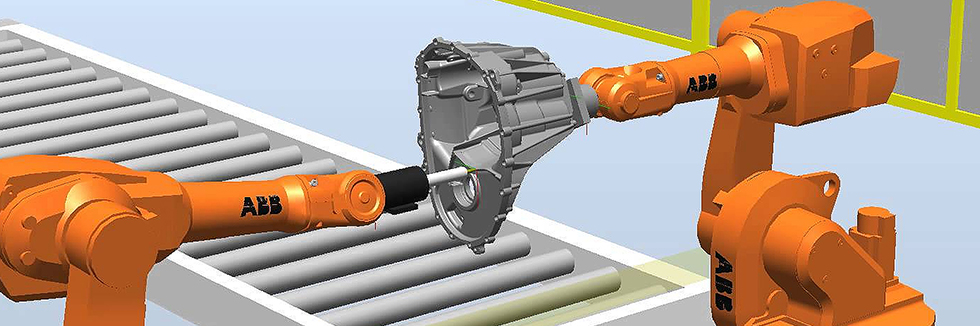

Digital Manufacturing is an integrated set of tools working with the definition of product data to support tool design, manufacturing processes design, visualization, simulation and other necessary tests to optimize the manufacturing process.

-

Cost reduction related to planning processes.

-

Reduced time-to-market, by reducing the time to start the production..

-

Reducing the number of prototypes using digital mockups (DMU) and simulation of manufacturing lines.

-

Storage of generated information (manufacturing instructions, resources, simulations, etc.) enables the validation of future projects and decreased time spent with future modifications.

-

Increased quality through verification / simulation of manufacturing processes.

-

Implementation of DFM technique (Design for Manufacturing) through the integration of product design, manufacturing planning and suppliers. From there, it creates a collaborative environment between these actors.

-

Return of investment (ROI) of up to two digits, payback period scaled within months.

-

Manufacturing processes validation through simulations before the start of production, that is, before any production resource is used.